Miscellaneous Steel Detailing is a critical aspect of modern construction projects. This process involves creating detailed drawings and designs for steel components not part of the main structural frame, such as stairs, handrails, and other architectural features. This article will provide an overview of the importance of miscellaneous steel detailing in construction projects, the steps involved in the process, best practices for successful detailing, and the tools and technologies used in the field.

What Is Miscellaneous Steel Detailing?

Miscellaneous Steel Detailing refers to creating detailed drawings and designs for steel components not part of the main structural frame. These components may include stairs, handrails, ladders, and other architectural features that require precise fabrication and installation. Fabricators and installers use the drawings created during the detailing process to produce the steel components and ensure they are installed correctly.

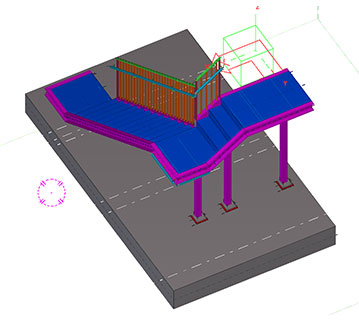

Various types of steel can be used in Miscellaneous Steel Detailing, including carbon steel, stainless steel, and aluminium. The choice of steel depends on the application and the project's specific requirements. For example, applications of Miscellaneous Steel Detailing in construction include the fabrication of stairs, railings, platforms, canopies, and other architectural features.

The Process of Miscellaneous Steel Detailing

The process of Miscellaneous Steel Detailing involves several steps. The first step is to create a 3D model of the structure using software such as AutoCAD, Revit, or Tekla Structures. Once the model is complete, the steel detailer can create detailed drawings for the steel components. These drawings must be precise and include all necessary dimensions, materials, and finishes.

Critical considerations in the Miscellaneous Steel Detailing process include communication and coordination with other trades involved in the project, including architects, engineers, and general contractors. In addition, the detailer must ensure that their drawings are compatible with the overall design and construction plans and that any potential issues are identified and addressed early in the process.

What Is The Role of Miscellaneous Steel Detailing in Construction Projects?

Using Miscellaneous Steel Detailing in construction projects offers several advantages. These include faster and more accurate fabrication and installation, reduced material waste, and improved project coordination. Additionally, using steel components can result in a more aesthetically pleasing finished product, as these components can be customized to match the overall design of the building.

Some Best Practices for Miscellaneous Steel Detailing

For successful Miscellaneous Steel Detailing projects, it is essential to follow several fundamental principles. These include effective communication and collaboration with all stakeholders, using the latest software and technologies, and adherence to industry standards and best practices. Additionally, it is essential to avoid common mistakes, such as incorrect dimensions or materials, and to ensure quality control throughout the fabrication and installation process.

What Tools And Technologies Are Used For Miscellaneous Steel Detailing?

Various tools and technologies are used in Miscellaneous Steel Detailing, including software such as AutoCAD, REVIT, and TEKLA Structures. These software programs allow for creation of precise 3D models and detailed drawings for steel components. In addition, advancements in steel detailing software have made the process faster and more efficient, allowing for faster fabrication and installation times.

The future of Miscellaneous Steel Detailing tools and technologies will likely include even more advanced software programs and tools, including virtual reality and augmented reality technologies.

Miscellaneous Steel Detailing in Practice

Examining case studies of successful projects is essential to understand the practical application of miscellaneous steel detailing. In addition, these case studies can provide insight into the benefits of using miscellaneous steel detailing and how it can improve the efficiency and quality of construction projects. However, it is also essential to acknowledge the challenges faced in miscellaneous steel detailing projects, such as coordination issues, design changes, and fabrication errors. By understanding these challenges, professionals in the field can learn important lessons and improve their processes for future projects.

Case Studies

The One World Trade Center in New York City: This iconic building features an intricate stainless steel spire designed and fabricated using miscellaneous steel detailing techniques. The spire, which stands 408 feet tall, required precise fabrication and installation to ensure it could withstand high winds and seismic activity.

The London Olympic Stadium: The stadium's roof was fabricated using a combination of steel and cable netting, which required meticulous detailing and coordination between the design team, fabricators, and installers. The result was a lightweight and durable roof structure that provided an unobstructed view for spectators.

The Shard in London: This 87-story skyscraper features a unique glass and steel facade created using bespoke steel sections and cladding. The intricate design required precise detailing and fabrication to ensure the steel components fit together seamlessly.

While these projects were complex and required advanced skills and expertise, they demonstrated the importance of miscellaneous steel detailing in achieving successful construction projects.

In conclusion, miscellaneous steel detailing is a critical component of construction projects that require accurate and timely fabrication and installation of non-structural steel components. This article has provided an overview of the definition, types of steel used, applications, process, importance, advantages, and best practices of miscellaneous steel detailing. It has also explored the tools and technologies used in the field and case studies of successful projects and the challenges and lessons learned from them. Professionals in the industry need to continue to learn and apply miscellaneous steel detailing techniques to ensure the success and safety of construction projects. Head to our official website to learn about miscellaneous steel detailing services. We offer a range of detailing services, including Stair Handrail Detailing Drawings - Staircase Handrail Detailing, Precast detailing, Rebar detailing, and main steel detailing.

Learn why outsourcing structural steel detailing services can help your save time, hire experts at lower prices, and save time.

ReplyDelete