Mechanical, electrical, and plumbing (MEP) system design coordination is a work-intensive approach carried out during the pre-construction stage of building projects. The increased use of BIM technology by AEC companies has led to the development of novel techniques for MEP BIM coordination.

|

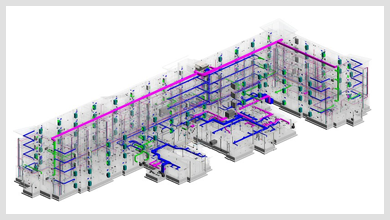

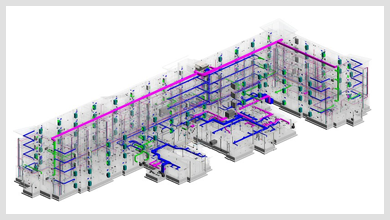

| BIM Coordination Model |

The construction sector has been moving toward digitization in recent years. As a result, the application of Building Information Modeling (BIM) has been gaining recognition globally, as it can increase productivity, improve coordination between project stakeholders, and reduce errors. The structural, architectural, mechanical, electrical, and plumbing (MEP) fields are involved in construction projects, and each discipline has its own set of BIM requirements.

The various approaches to BIM-based MEP coordination vary depending on the project and team's needs. However, the MEP BIM coordination approach includes -

|

| 3D MEP Coordination Model In Navisworks |

-

More quickly identifying and resolving clashes between MEP systems, Improved communication, and coordination between project team members, Creating a more accurate and detailed project model,

-

The need for accurate clash detection,

-

The importance of having a clear and concise BIM model,

-

The need for quality assurance,

-

The ability to save time and money, improve communication, and

-

Increase the accuracy of the coordination process,

-

The utilization of BIM software in construction projects,

-

Elements of data gathered to keep track of the coordination process;

-

Coordination production rate-influencing factors;

-

AEC businesses' preferred metrics for gauging production rate;

-

Identified recommended practices that companies use to improve the use of BIM in the coordination process.

The most often acquired information by AEC companies throughout the MEP coordination process was team members' BIM competency and the number of trades present at meetings. The team experience, the preliminary design's caliber, and the MEP system's complexity were the most important variables influencing the MEP coordination process. Participants in this study suggested several best practices to boost the effectiveness of the MEP coordinating process.

Comments

Post a Comment